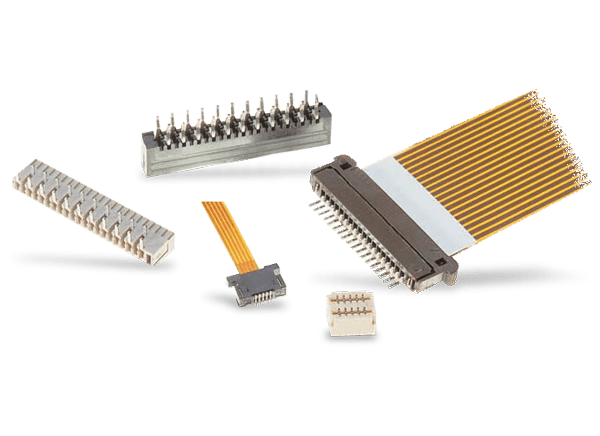

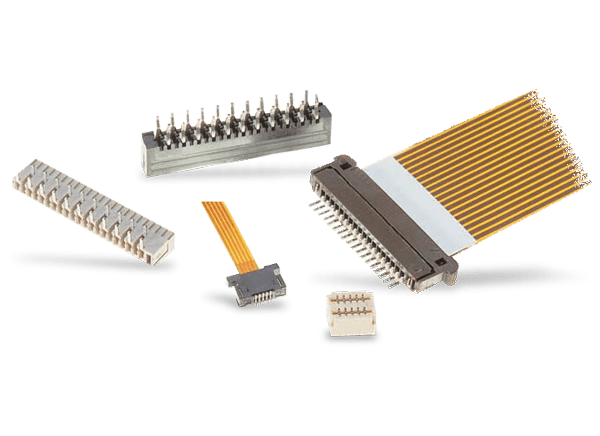

The FFC connector is used to connect the strip flat flexible cable (FFC) to the PCB circuit. They also provide a cable-to-cable configuration. These connectors have a high density and very narrow shape size, suitable for small space. They are commonly used in consumer applications, such as laptops, cameras, computer peripherals, appliances, and telephones. Single or double row connector shells are usually made of flexible plastic, polymer, engineered rubber or film around the embedded metal connectors. Meanwhile, there are multiple locking styles.

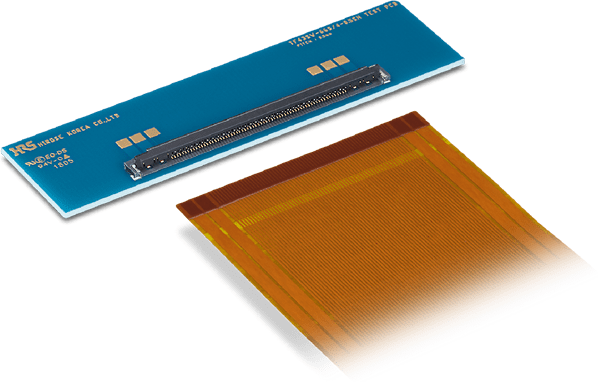

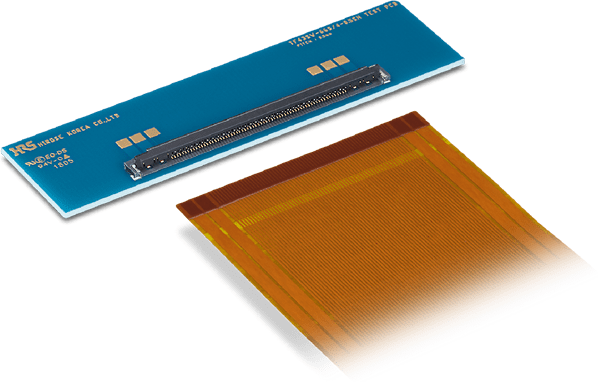

The FPC connecor connects the flexible printed cable (FPC) to the circuit board. The FPC is an FFC in which the conductor is printed on a cable substrate rather than embedded therein. The FPC / FFC connectors are sometimes called ribbon connectors.

One key reason for the designers to choose FFC / FPC connectors is that they have higher flexibility when compared with conventional rigid circuit boards when used with flexible cables.

ELCO is an early developer of the FFC type connector, merging with AVX in the early 1990s. Then KYOCERA AVX took responsibility for the ELCO product and continued to develop its FFC / FPC line.

Although FFC was widely used in the 1970s, the cable was originally only in direct welded or crimp contact versions. In 1986, ELCO invented the 8370 series, the first premium card-edge connector to be directly attached to the FFC.

Unique contact actuator is designed with fixed pieces to prevent accidental actuator separation. The fixed piece circles the actuator shaft and hooks to the chamber to prevent the actuator from opening.

Design notes

• FFC / FPC connectors offer pins, socket, card edges, and pad contacts with single or double row housing.

• Certain variants can mix FFC cables and circular wire contacts to provide multiple spacing, such as 0.03 mm, 0.5 mm, 1.00 mm, 1.25 mm, 2.54 mm, but the most common are 0.500 mm, 1.00 mm and 1.25 mm. A single FFC can have different spacing between different conductors on the same cable, but this is not common.

The FFC /

FPC connector provides a fully shielded version to control the EMC

interference.

Various

locking mechanisms can hold this connector type, including latches, pins,

and fixing plates.

Circuit

board termination options include surface mounting or through-holes.

The 0.5 mm spacing

shield FFC / FPC connector has one-hand automatic locking function, high

temperature resistance (125 °C), high speed performance, and vertical or horizontal

wiring.

Market, sector, and

applications

-

Automotive, consumption, data

communications / telecommunications, testing and measurement, medical, and

industry.

-

FFC / FFP connectors serve a wide range of

markets and applications, including consumer equipment, industrial

controls, displays, printers, automobiles, testing and measuring

instruments, electrical and medical equipment.

-

See: FFC /

FFP Connectors for automotive applications

The FFC / FPC one-click connector has a single-step

connection, automatic locking mechanism and high retention force for reliable

connection and ease of operation. These connectors provide visible release

buttons for easy operation of FFC / FPC cable release, and provide a locking

system ensuring FFC / FPC cable connections through high retention forces.